Choosing the right fabricante de sofá for your furniture import business is essential to ensuring quality, competitive pricing, and customer satisfaction. Here’s a detailed guide on how to determine if a sofa manufacturer meets your import needs:

I. Define Your Import Needs

Product Positioning:

- Identify whether the sofa is intended for the high-end, mid-range, or budget market.

- Example: High-end markets require premium materials, superior craftsmanship, and sophisticated design.

Style and Design:

- Specify the desired style, such as modern minimalist, European classic, or traditional.

- Consider the uniqueness and appeal of the design to meet the target market’s aesthetic preferences.

Size and Specification:

- Determine the common sizes and specifications based on your customer base.

- Example: Larger sofas may be preferred in certain regions, while smaller, versatile options might be popular in urban areas.

Quality Criteria:

- Set standards for the sturdiness of the frame, comfort and durability of padding, and fabric quality.

- Example: High-quality requirements might include solid wood frames and imported fabrics.

Quantity and Delivery:

- Estimate your import quantities and required delivery timelines to ensure the manufacturer can meet these needs.

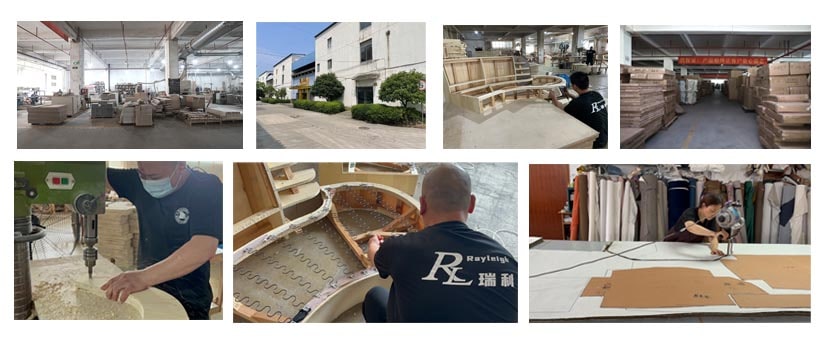

II. Examination of the Sofa Manufacturer

Production Capacity:

Factory Size:

- Examine the size of the fábrica de sofás, plant area, and workforce.

- Example: A large factory with extensive floor space and a sizable workforce may be better equipped to handle large orders.

Equipment and Technology:

- Assess the sophistication of production equipment, such as automated cutting machines and advanced sewing machines.

- Example: Factories using 3D printing technology for mould making may offer higher precision and efficiency.

Production Capacity Assessment:

- Inquire about monthly or annual production capacity and peak order handling.

- Review past production records and delivery performance to verify capacity claims.

Quality Control System:

Inspection Standards:

- Review standards and processes for inspecting raw materials, semi-finished products, and finished products.

- Example: Standards might include moisture content tests for wood and abrasion tests for fabrics.

Inspection Equipment and Personnel:

- Check for professional quality inspection equipment and experienced inspectors.

- Example: Pressure testing machines and color difference detectors ensure product quality accuracy.

Quality Tracing System:

- Confirm the existence of a traceability system to quickly locate and resolve quality issues.

Design and R&D Capability:

Design Team:

- Investigate the professional background and experience of the design team.

- Example: Manufacturers with renowned designers often provide innovative and competitive products.

New Product Development:

- Assess the frequency and process of new product development.

- Example: Manufacturers introducing several new collections annually can adapt to market trends.

Customization Capabilities:

- Evaluate the manufacturer’s ability and experience in custom production to meet specific design needs.

Raw Material Sourcing:

Supplier Management:

- Examine how the manufacturer selects and manages raw material suppliers.

- Example: Consistent quality from suppliers ensures stable raw material standards.

Environmental and Sustainability:

- Check if raw materials meet environmental standards and if there is a sustainable sourcing policy.

Price and Cost:

Quotation System:

- Request a detailed quotation covering costs like raw materials, labor, and transportation.

- Example: A transparent quotation system helps analyze costs and compare prices effectively.

Price Competitiveness:

- Compare the manufacturer’s prices with others, considering product quality and services.

Cost Control:

- Learn about the manufacturer’s strategies for maintaining reasonable prices while ensuring quality.

Delivery and Logistics:

Delivery Time Commitment:

- Verify the delivery timelines and review past delivery records for accuracy and reliability.

Logistics Partners:

- Assess the reliability and cost-effectiveness of logistics partners and transportation modes used.

After-sales Service:

Warranty Policy:

- Inquire about the product warranty duration and scope.

- Example: Longer warranty periods with comprehensive coverage reduce after-sales risks.

Troubleshooting:

- Understand the manufacturer’s process and response time for handling quality issues or customer complaints.

Site Visits and Case Studies:

Factory Tour:

- Observe the production site’s orderliness, worker conditions, and storage standards for raw materials and finished products.

Communication with Employees:

- Engage with frontline workers and management to understand their perspectives on production processes and quality control.

Successful Cases:

- Request case studies to learn about the manufacturer’s cooperation with other importers and customer feedback.

III. Comprehensive Assessment and Decision-making

Strengths and Weaknesses:

- List and analyze the manufacturer’s strengths and weaknesses in relation to your business needs.

Risk Assessment:

- Evaluate potential risks such as quality or delivery issues and develop mitigation strategies.

Co-operation Prospects:

- Consider the long-term prospects for collaboration and whether the manufacturer can grow with your business.

Determining the right sofa manufacturer for your furniture import needs involves a thorough examination and analysis of various factors. This complex but vital process requires investment in time and effort to ensure you make an informed decision, laying a solid foundation for your import business. Regular follow-up and reviews will ensure continuous improvement and alignment with your business goals.