Evaluating the production process of a sofa factory is crucial for ensuring high product quality, efficient production, and competitiveness in the market. Here’s a comprehensive guide on how to meticulously assess the production process of a sofa factory:

I. Raw Material Procurement and Management

Supplier Evaluation:

- Review the list of raw material suppliers.

- Assess the suppliers’ credibility, scale, and industry reputation.

- Evaluate their quality control systems and reliability in providing standard-compliant materials.

Purchasing Plan:

- Check if the procurement planning is scientifically based on production needs and inventory status.

- Assess the flexibility of the purchasing plan to handle market changes and unexpected situations.

Raw Material Inspection:

- Examine the factory’s standards and procedures for raw material inspection, covering appearance, size, and performance.

- Review the inspection equipment and staffing for accuracy and reliability.

Inventory Management:

- Evaluate the raw material warehouse layout and management style, ensuring clear categorization and labeling.

- Assess the inventory turnover rate to avoid backlogs or shortages affecting production.

II. Design and Development

Design Team:

- Understand the composition and background of the design team.

- Evaluate their innovation capabilities in introducing new styles to meet market demands.

Design Process:

- Assess the clarity and efficiency of the process from conceptual design to detailed drawings.

- Observe the communication and collaboration between design and production departments.

Sample Making:

- Inspect the equipment and process for sample making to reflect the design intent accurately.

- Review the sample testing and improvement processes considering user experience and quality requirements.

III. Trimming and Cutting

Cutting Equipment:

- Check the precision and efficiency of cutting equipment like laser cutting machines and CNC machines.

- Understand the maintenance practices to ensure long-term stable operation.

Nesting Optimization:

- Observe how materials are nested to minimize waste.

- Assess the use of advanced nesting software for improving material utilization.

Cutting Quality:

- Sample check the cut parts for dimensional accuracy, edge flatness, and cut quality.

- Review the control standards and error-handling methods in cutting.

IV. Sewing and Stitching

Sewing Equipment:

- Inspect the sewing equipment’s brand, model, and suitability for production demands.

- Check the equipment’s debugging and maintenance for consistent sewing quality.

Sewing Techniques:

- Evaluate workers’ sewing skills, including stitch length and aesthetics.

- Observe the process at patchworks and corners for flatness and smoothness.

Quality Inspection:

- Review the furniture factory‘s inspection standards and procedures for sewing quality.

- Check the measures for repairing and handling non-conforming products.

V. Frame Production

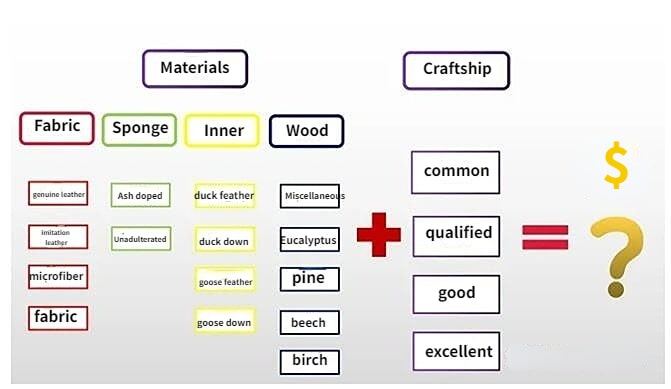

Frame Material:

- Verify the quality and specifications of wood or metal materials used.

- Confirm proper drying, anti-insect, and anti-corrosion treatments.

Frame Assembly:

- Observe the craftsmanship of frame assembly, ensuring precise construction and firm joints.

- Assess the quality control in the assembly process for dimensional and structural checks.

Reinforcement:

- Investigate the reinforcement methods for critical areas like armrests and backrests.

- Check for pre-compression treatment to prevent deformation.

VI. Filling and Upholstery

Filling Material Selection:

- Check the quality and density of filling materials like sponge, down, and springs.

- Review the upholstery material suppliers and quality test reports.

Filling Process:

- Observe the even distribution and fullness during the filling process.

- Assess the filling volume and hardness control for ergonomic comfort.

Upholstery Quality:

- Inspect the fit and flatness of fabric or leather upholstery.

- Check the finishing process for closures and edging for fineness and aesthetics.

VII. Assembly and Integration

Assembly Process:

- Understand the standardised operation process for assembly.

- Observe the use of tools and equipment for efficiency.

Matching of Parts:

- Check the size, shape, and interface matching of components during assembly.

- Evaluate the overall appearance and structural stability post-assembly.

Detailed Finishing:

- Pay attention to the fine detailing, such as foot installation and decorative part fixing.

- Ensure final cleaning and finishing work is carried out.

VIII. Quality Control and Inspection

Inspection Link Setting:

- Review the inspection points during production, including raw material, process, and finished product inspections.

- Assess the qualification and experience of inspectors.

Inspection Standards:

- Check the detailed quality inspection standards covering appearance, size, performance, and durability.

- Confirm compliance with relevant regulations and standards.

Inspection Equipment and Methods:

- Examine the testing equipment like pressure and wear testing machines.

- Verify the scientific and accurate testing methods, and regular calibration and validation.

Quality Problem Handling:

- Understand the handling process and traceability mechanism for quality issues.

- Evaluate continuous improvement measures based on quality data analysis.

IX. Production Scheduling and Management

Production Planning:

- Check if the production plan is reasonably arranged according to order priority, delivery date, and capacity.

- Evaluate the visualization and update frequency of the production plan.

Progress Tracking:

- Review how the sofa factory tracks production progress using information technology systems.

- Observe the early warning and handling mechanism for delays.

Resource Allocation:

- Examine the allocation of resources like manpower, equipment, and raw materials.

- Evaluate strategies for resource allocation during peak and low seasons.

Teamwork:

- Observe the communication and cooperation between production departments.

- Review team-building and incentive measures to improve staff collaboration.

X. Environmental Protection and Production Safety

Environmental Protection Measures:

- Check the sofa factory’s facilities and measures for waste treatment.

- Review the use of environmentally friendly materials and processes.

Safe Production:

- Examine the production safety system and training programs.

- Check safety equipment and warning signs for employee protection.

By thoroughly assessing these aspects, you can gain a detailed understanding of the sofa factory’s production capacity, quality level, and management efficiency. This evaluation provides a strong basis for purchasing decisions, cooperation negotiations, or production improvements, helping to choose a quality partner or enhance your own fabricant de canapés‘s competitiveness. Regular follow-up and review of assessment results ensure continuous improvement and optimization of the production process.