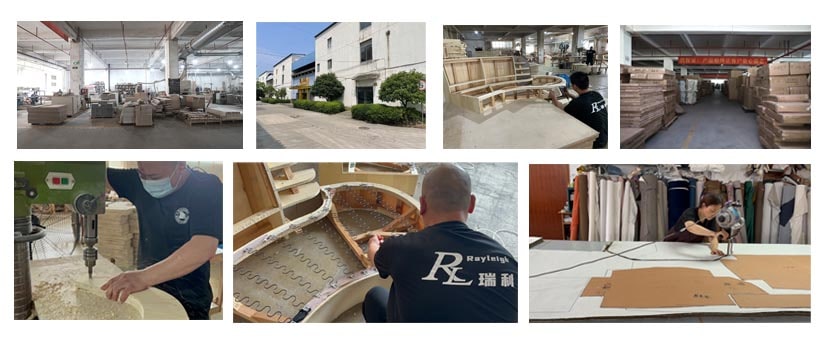

Visiting a sofa factory is a crucial step in finding a reliable sofa supplier. Evaluating a sofa factory’s production capacity is essential to determining whether it can meet your needs and deliver quality products on time. Below, let’s discuss how to comprehensively and accurately assess the production capacity of a sofa factory during a site visit.

I. Assessment of Production Equipment and Technology

Advanced and efficient production equipment is an important support for a sofa factory’s production capacity.

1. Advancement and Diversity of Equipment

- Observation: Check if the factory’s equipment is industry-leading. For example, modern CNC cutting equipment can precisely cut fabrics and leathers, greatly improving efficiency and precision. High-precision sewing machines ensure even and firm stitching, enhancing the overall quality of sofas.

- Advanced Equipment: Intelligent filling and assembly equipment is a strong indicator of a factory’s robust production capacity.

2. Maintenance and Renewal of Equipment

- Maintenance: Good maintenance is crucial for the normal operation and longevity of equipment. Verify if equipment is regularly maintained and repaired, and check for signs of wear, malfunction, or aging.

- Upgrades: Inquire if the factory plans to upgrade its equipment to meet evolving market demands and technological advancements.

3. Technological Innovation and Application

- Innovation: Note if the factory adopts new production technologies, like 3D printing for canapé parts or environmentally friendly water-based adhesives. Such innovations not only enhance production efficiency and product quality but also demonstrate the factory’s competitiveness and foresight in the industry.

II. Sofa Factory Size and Layout Considerations

The scale and layout of a sofa factory largely determine its production capacity and the efficiency of its production process.

1. Floor Space and Factory Space

- Space: Large factories usually have more production area to accommodate additional production lines and storage facilities. Assess the footprint of the factory to determine if it has room for future expansion.

2. Number and Configuration of Production Lines

- Production Lines: Multiple parallel production lines indicate the ability to handle multiple orders simultaneously, increasing production efficiency. Check the spacing between production lines and the convenience of material transport, as this impacts the smoothness of production.

3. Warehousing and Logistics Facilities

- Storage: An efficient warehousing and logistics system ensures a timely supply of raw materials and quick delivery of finished products. Check the storage capacity and management style of the raw material warehouse. Examine the shipping process and logistics capabilities of the finished goods warehouse.

III. Analysis of the Number and Skill Level of Workers

Workers are the direct executors in the production process, and their number and skill level directly affect production capacity.

1. Number of Workers and Team Size

- Workforce: Count the number of workers involved in sofa production, including those in cutting, sewing, and assembly. An adequate number of workers ensures timely completion of production tasks even during peak order periods.

2. Skillfulness of Workers

- Skills: Observe workers’ proficiency and accuracy in their tasks. Skilled workers complete more work per unit of time and ensure product quality.

3. Training and Skill Upgrading Mechanism

- Training: Find out if the factory provides regular training and skills upgrading courses for workers to adapt to new production techniques and processes. A factory that invests in staff development often maintains high productivity and product quality.

IV. Stability of Raw Material Supply

A stable supply of raw materials is the basis for continuous production.

1. Selection of Raw Material Suppliers

- Suppliers: Inquire about the factory’s raw material suppliers and their reputation. Long-term, stable relationships with reputable suppliers typically ensure the quality and timely supply of raw materials.

2. Raw Material Inventory Management

- Inventory: Check the inventory level of raw materials. Reasonable inventory meets production demand without causing excessive backlog. Verify if the factory’s inventory management system accurately controls inventory levels according to the production plan.

3. Raw Material Procurement Cycle

- Procurement: Find out the time required from placing a purchase order to the arrival of raw materials. A shorter procurement cycle reduces production delays due to raw material shortages.

V. Optimization of Production Process and Management

A scientific and reasonable production process and efficient management maximize the production capacity of the sofa factory.

1. Rationality of the Production Process

- Process: Observe the entire production process from raw material input to finished product output, looking for unnecessary steps or bottlenecks. An optimized process reduces production time and cost, enhancing efficiency.

2. Production Planning and Scheduling

- Planning: Learn how the factory develops production plans and schedules. Effective planning prioritizes orders and ensures timely completion.

3. Quality Management System

- Quality Control: Examine the factory’s quality management system, including quality control measures, standards, and testing methods. Strict quality management ensures product quality and prevents rework and delays.

VI. Review of Past Production and Delivery Records

Past performance is a key indicator of a factory’s production capacity.

1. Historical Production Data

- Data: Request production data for different product types and order sizes. Analyze trends and stability to understand performance under various conditions.

2. On-Time Delivery

- Delivery: Review on-time delivery records to assess the factory’s ability to deliver orders promptly. A high on-time delivery rate indicates good production organization and coordination.

3. Customer Satisfaction

- Feedback: Assess customer satisfaction with the factory’s production capacity and delivery performance through feedback and evaluation reports.

VII. Potential and Flexibility for Capacity Expansion

Consider the factory’s capacity expansion potential and flexibility to meet changing market demands.

1. Expandable Facilities and Planning

- Expansion: Check if the factory has reserved space or infrastructure for future expansion.

2. Possibility of Technological Upgrading

- Upgrading: Determine if the factory plans to introduce more advanced production equipment and technology.

3. Reserve and Deployment of Human Resources

- Human Resources: Ask about the factory’s human resource reserve and deployment mechanism to meet increased production demands.

VIII. Comprehensive Assessment and Case Study

To understand how to comprehensively assess production capacity, consider an actual case study.

Case Study

Suppose you are inspecting a usine de canapés. During the site visit, you find that the factory has:

- Advanced Equipment: Latest CNC cutting machines and automated sewing equipment, well-maintained and regularly updated.

- Large Scale: Five efficiently operating production lines, a reasonable layout, and convenient material transport.

- Skilled Workforce: Sufficient number of skilled workers, with regular training and skills upgrading courses.

- Stable Supply: Reliable raw material suppliers, scientific inventory management, and short procurement cycles.

- Optimized Process: Optimized production process, strict quality control, steady production volume growth, high on-time delivery rate, and good customer satisfaction.

- Expansion Plan: Clear capacity expansion plan, reserved space for expansion, strong technical upgrading, and human resources deployment capacity.

These factors indicate strong production capacity and potential for meeting order demands and future development.

To evaluate the production capacity of a sofa factory, consider various factors and gather comprehensive information through site visits, data reviews, and communication with management and workers. This ensures a wise decision in choosing a reliable furniture supplier capable of providing stable, high-quality products and timely delivery.