Visiting a sofa factory is a crucial part of the process of finding a quality sofa supplier. Not only does it give you a good idea of what the factory is actually like, but it also helps you make a more informed decision on how to cooperate. So, what exactly should you focus on when visiting a sofa factory? The following will be elaborated for you.

I. Factory’s Infrastructure and Production Environment

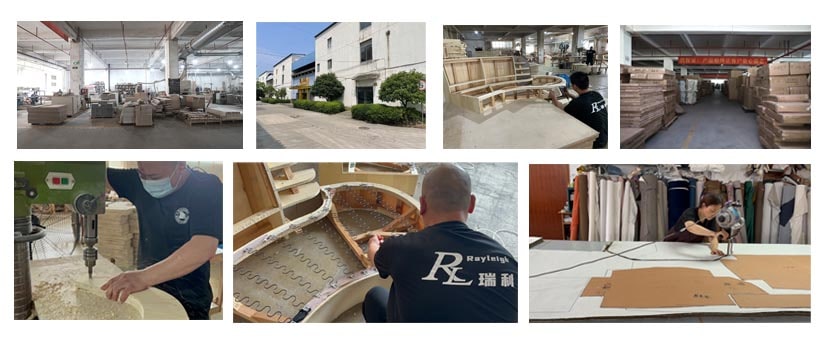

The factory’s infrastructure and overall production environment can reflect the standardization of its operation and management level.

1. Factory Size

- Observe the factory’s floor space, plant area, and the number and layout of production lines.

- Large-scale factories usually have stronger production capacity and resource deployment capabilities, and are able to cope with larger orders.

- However, this does not mean that small-scale factories are necessarily unreliable. Some small-scale factories may have unique advantages in specific areas or processes.

2. Workshop Layout

- A proper shop floor layout can help increase productivity and reduce material handling and waste in the process.

- Areas of production such as cutting, sewing, and assembly should be clearly delineated and have a smooth material flow.

3. Cleanliness and Hygiene

- A clean and tidy production environment is essential to ensure product quality.

- Dust, debris, etc., may affect the appearance and quality of the sofa, especially in leather and fabric handling.

4. Ventilation and Lighting

- Good ventilation ensures that workers work in a comfortable environment, reducing fatigue and improving the quality of work.

- Adequate lighting is conducive to the workers’ accuracy in operation and ensures production precision.

II. Production Equipment and Technology

Advanced production equipment and technology is the key factor to ensure the quality and production efficiency of sofas.

1. Advancement of Equipment

- Check the machines and equipment used in the factory, such as cutting machines, sewing machines, hemming machines, and so on.

- Modern CNC equipment can improve production accuracy and efficiency, while outdated equipment may lead to unstable product quality.

2. Maintenance Status of the Equipment

- Good maintenance of equipment not only prolongs its service life but also ensures its normal operation and production accuracy.

- Check whether the equipment is regularly maintained and whether there are any obvious signs of failure or wear and tear.

3. Technological Innovation

- Find out whether the sofa manufacturer is constantly introducing new production techniques and technologies to improve the competitiveness of its products.

- For example, whether new sewing techniques, filling processes, or environmentally friendly treatments have been adopted.

III. Purchase and Management of Raw Materials

The quality of raw materials directly determines the quality and durability of sofas.

1. Raw Material Suppliers

- Ask the factory’s main suppliers of raw materials about their reputation and quality stability.

- Well-known suppliers usually provide better quality raw materials.

2. Storage of Raw Materials

- Observe the storage conditions of the raw materials, such as whether the wood is stored moisture-proof, and whether the leather and fabric are protected from direct sunlight and a humid environment to prevent deformation and deterioration.

3. Raw Material Inspection

- Understand the factory’s inspection process and standards for raw materials, whether there are strict incoming inspection links to ensure that the raw materials meet the quality requirements.

IV. Production Process and Quality Control

Efficient production process and strict quality control is the core to ensure the quality of sofas.

1. Rationality of Production Process

- Observe the whole production process, from raw material processing to finished product assembly, whether it is reasonable and smooth, whether there are bottlenecks or unnecessary processes.

2. Quality Control Link

- Understand the quality control system of the factory, including inspection in the production process and finished product inspection.

- Check the inspection standards and inspection records to ensure that there is quality control in every process.

3. Handling of Non-Conforming Products

- Ask the factory for the treatment of substandard products, whether there are traceability mechanisms and improvement measures to avoid recurrence of the problem.

V. Workers’ Skills and Training

Skilled and well-trained workers are important human factors to ensure product quality.

1. Worker Skill Level

- Observe the operation proficiency of the workers, their performance in cutting, sewing, and assembling can reflect their skill level.

2. Training System

- Find out whether the factory provides regular training and skill enhancement opportunities for workers to adapt to changing production requirements and technology updates.

VI. Product Design and R&D Capability

Having innovative design and R&D capability can make the factory stand out in the market competition.

1. Design Team

- Find out whether the factory has a professional design team and how their design concept and experience are.

2. Sample Display

- Check the factory’s sample display area to assess the design style, style diversity, and innovation of its products.

3. Customization Capability

- Ask whether the factory is capable of customized design and production according to customers’ special needs, and its experience and process in customized projects.

VII. Environmental Protection and Safety Measures

In today’s era of focusing on environmental protection and sustainable development, the factory’s environmental protection and safety measures should not be overlooked.

1. Environmental Protection Measures

- Find out how the sofa factory treats wastewater, waste gas, and waste residue in the production process and whether it meets the requirements of environmental regulations.

2. Production Safety

- Check whether the factory is equipped with necessary safety facilities, such as fire-fighting equipment and protective gear, as well as whether there is a sound production safety system and training.

VIII. Management Team and Corporate Culture

A good management team and positive corporate culture can promote the sustainable development of the factory.

1. Experience and Philosophy of the Management Team

- Communicate with the factory’s management team to understand their industry experience, management philosophy, and plans for future development.

2. Corporate Culture

- Feel the factory’s corporate culture, whether it focuses on quality, integrity, customer service, and staff development.

IX. Factory’s Reputation and Customer Evaluation

Before the inspection, you can learn about the factory’s reputation and word of mouth through internet search and industry reports.

1. Customer List

- Check the list of customers that the factory has cooperated with, especially some famous brands or large enterprises, which can prove its strength and reputation to a certain extent.

2. Testimonials

- If possible, contact the factory’s current or past customers to learn about their experience and evaluation of the factory.

X. Price and Delivery Time

Although this is not a factor that can be fully determined during the site visit, it is possible to have preliminary communication and understanding with the factory.

1. Price System

- Understand the factory’s price structure and pricing strategy, whether reasonable and transparent.

2. Delivery Time Commitment

- Ask the factory about the delivery time commitment for different order sizes, and find out how it guarantees on-time delivery.

Conclusion

To sum up, a site visit to a sofa factory requires a comprehensive and detailed observation and understanding from many aspects. By focusing on these key aspects, you will be able to more accurately assess the factory’s strengths and potentials, and thus choose a reliable partner for your business. Remember to ask more questions, observe, and compare during the inspection process, and don’t be fooled by superficial phenomena to ensure your investment and cooperation can bring satisfactory returns.